CoverPiù

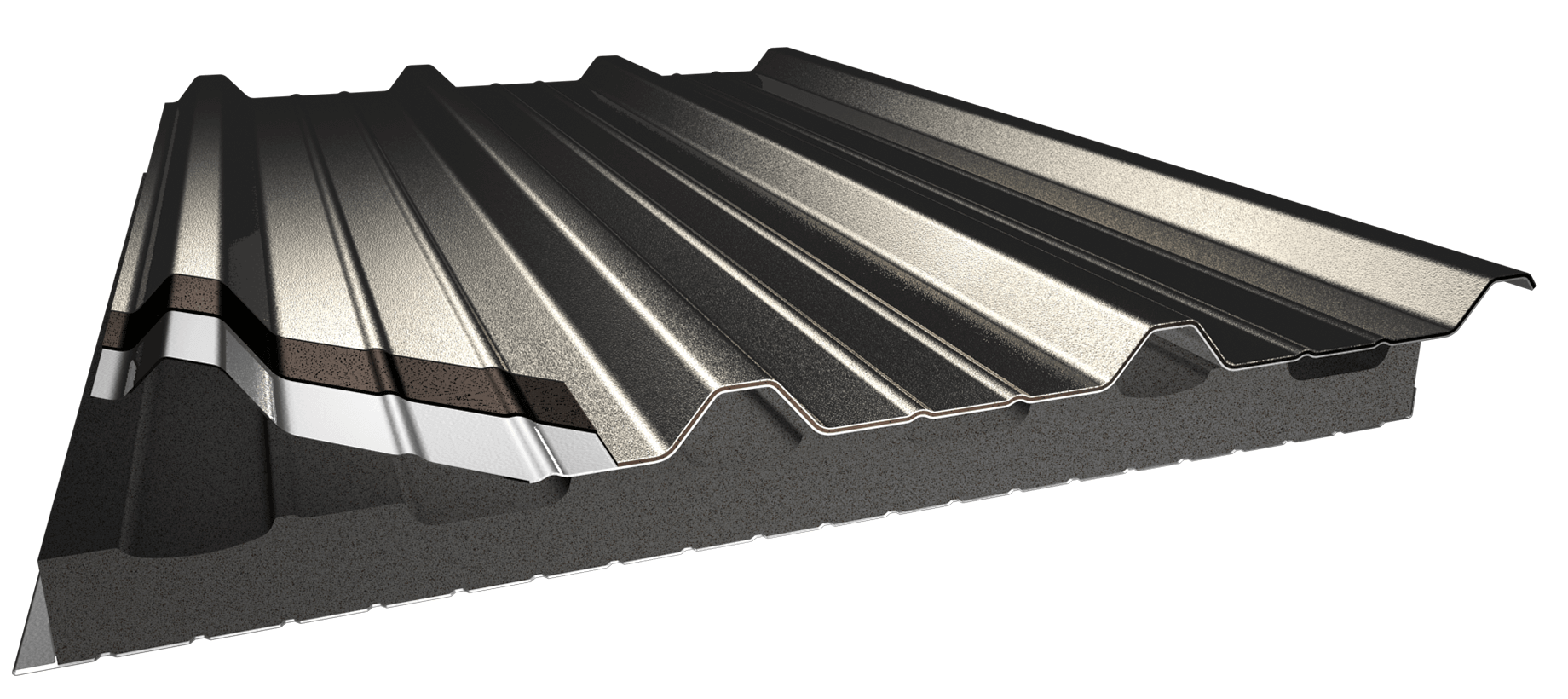

Micro-ventilated sandwich panel for discontinuous structures.

Coverpiù is the micro-ventilated sandwich panel with multi-layer technology. It ensures thermal andacoustic comfort. The micro-ventilation of the multi-layer sheet on top enhances durability.

Distinctive features of CoverPiù

Certifications

The roofing system ensures the following performances:

|

Reaction to fire: |

B, s2-d0 UNI EN 13501-1; EN 13823; EN ISO 11925-2 |

|

Fire forformance from outside: |

BRoof T3 UNI EN 13501-5; UNI CEN/TS 1187 |

|

Thermal transmittance: |

0,31 W/m2 K for 100 mm thickness 0,26 W/m2 K for 120 mm thickness 0,22 W/m2 K for 140 mm thickness 0,19 W/m2 K for 160 mm thickness |

|

Solar Reflectance Index (SRI): |

External surface: Natural aluminium surfacing (N) 107% Colored Aluminum: Off White RAL 9002 (W) 73% |

CoverPiù

For your project

Contact our team

CoverPiù: the sandwich panel with multi-layer protection, ideal for thermal and acoustic insulation.

In public construction or real estate management contexts, it is essential to choose roofing solutions that ensure housing comfort and time savings. Coverpiù provides thermal comfort and acoustic insulation. BRoofT3 certified, it is the ideal support for photovoltaic systems.